[最も共有された! √] first floor suspended concrete slab detail 818898

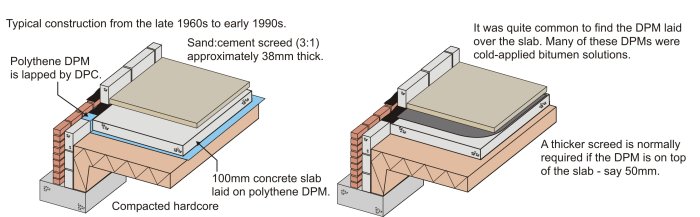

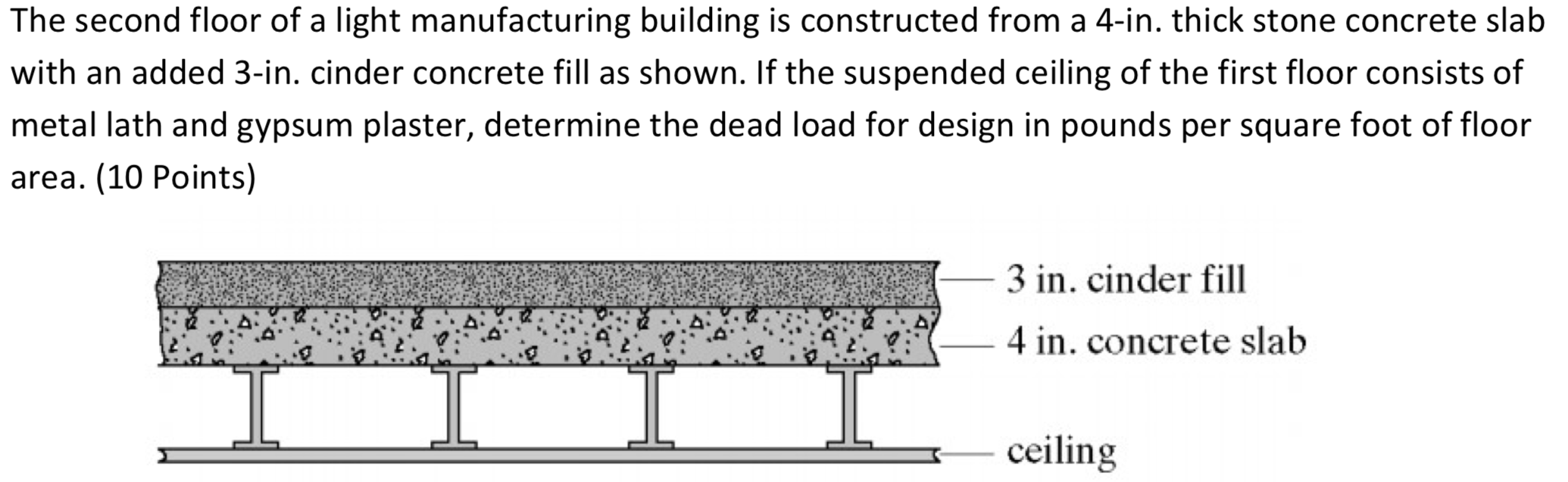

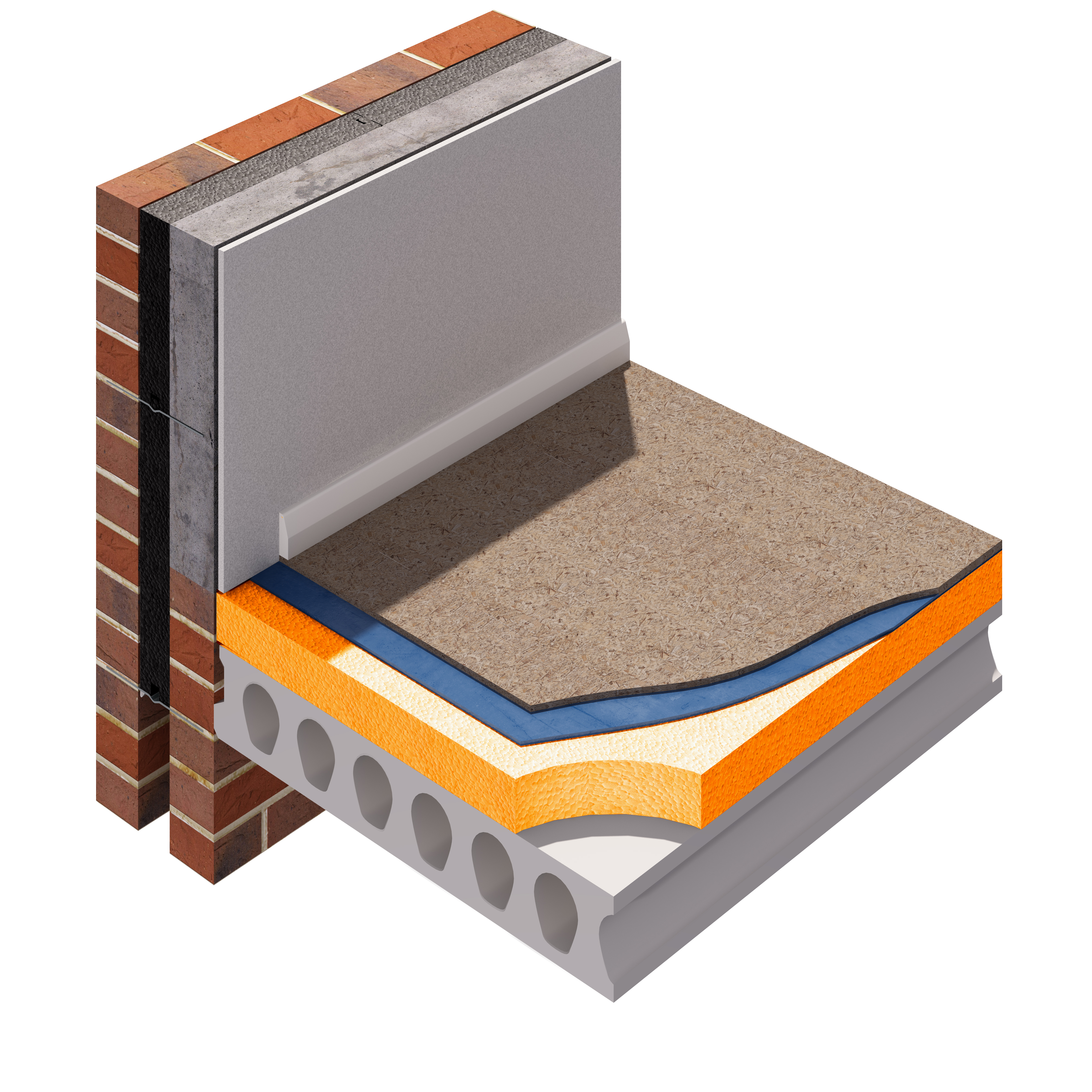

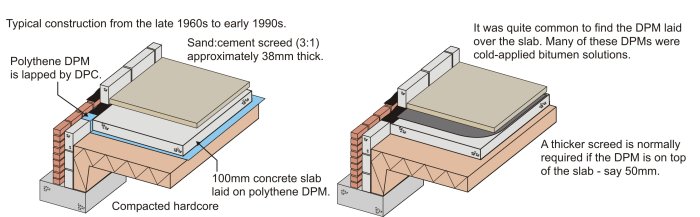

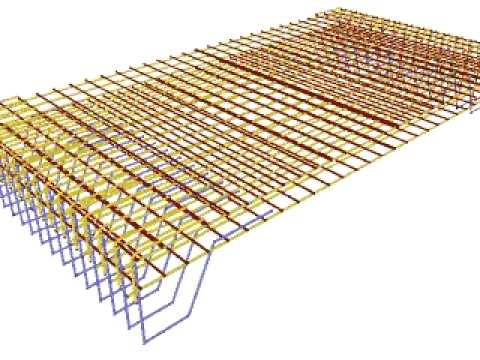

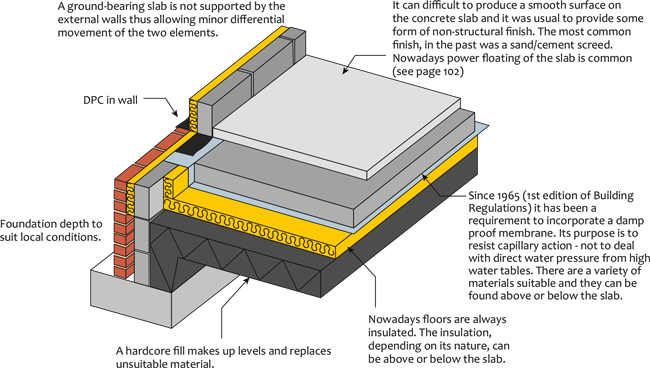

Solid concrete floors are typically built in six layers (plus two more if you include underfloor heating and the floor coverings) The key stages are The oversite area is stripped of vegetation and topsoil Then a base of clean hardcore at least 100mm thick is laidWhether it's a slabonground for your Ground Floor, or a suspended slab for your First Floor, a concrete solution is going to cost more money – in materials, labour, and time A slab will require formwork, steel reinforcement, pump hire on the day of the pour, and finishing costs (for example, unless you opt for a polished concrete finish, you'll still need to build either a solidE5MCFF30 Suspended InSitu Concrete Floor, Insulation Below Slab Build Up External Masonry Cavity Wall Masonry Outer Leaf (λ = 077) 100mm Aircrete Block Inner Leaf (λ = 019 W/mK) Full Fill Insulation 150mm Cast InSitu Suspended Slab 100mm Insulation Below Slab (0022W/mK)

Greenspec Housing Retrofit Ground Floor Insulation

First floor suspended concrete slab detail

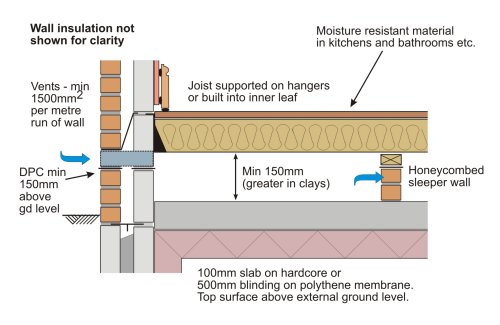

First floor suspended concrete slab detail-Precast suspended slabs are constructed by pouring the slabDuring the first years of the century suspended timber floors changed A number of improvements were introduced, mostly damp related In the graphic below note that the entire floor is separated from the substructure by the DPCs In addition, the bare earth is covered with a concrete slab (often referred to as an 'oversite') which is at, or above, external ground level to

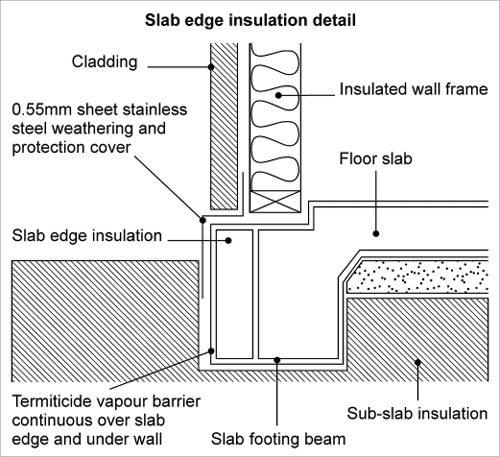

Evolution Of Building Elements

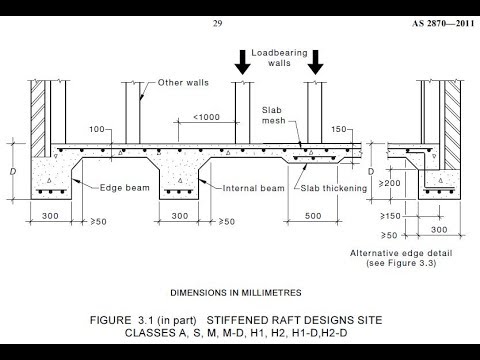

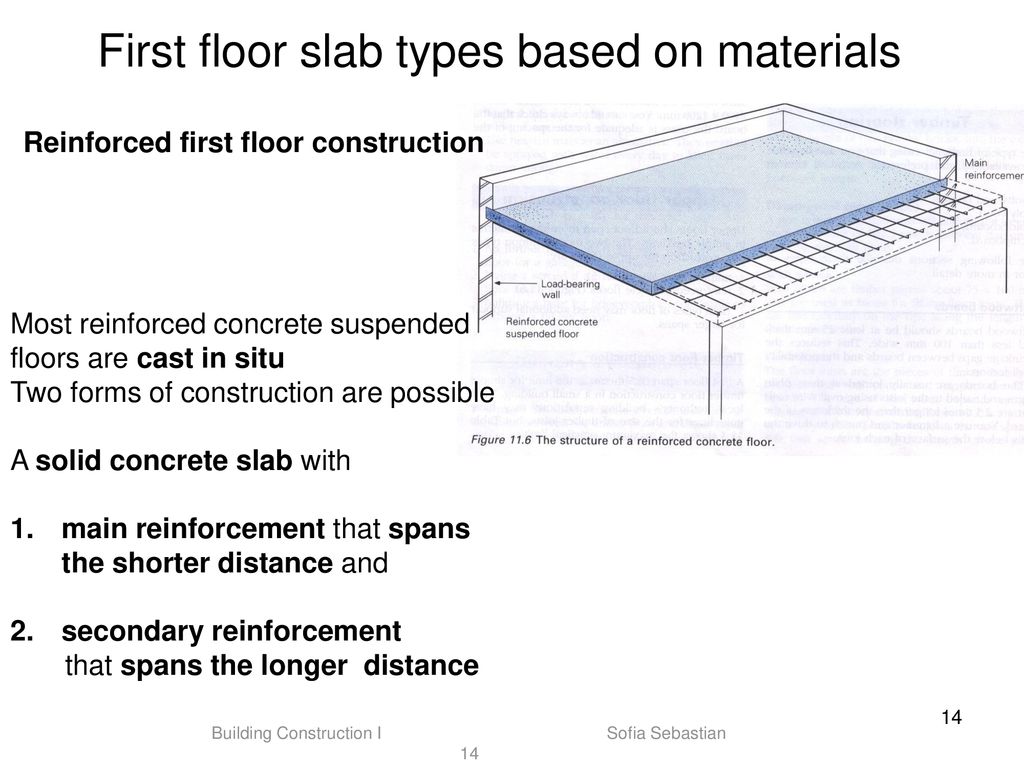

During the first years of the century suspended timber floors changed A number of improvements were introduced, mostly damp related In the graphic below note that the entire floor is separated from the substructure by the DPCs In addition, the bare earth is covered with a concrete slab (often referred to as an 'oversite') which is at, or above, external ground level toA concrete slab (or suspended beam and block construction) is laid over a damp proof membrane A mm thick piece of insulation is fixed to the perimeter (external) walls, to a height to include the depth of floor insulation and screed Whilst the edging insulation may be on show, it is covered by wall plastering and skirting boards Firstfloor slab thickness The normal thickness used for reinforced concrete slabs in South Africa is 170 mm for small slabs, 255 mm for slabs larger than 5m x 5m and 340 mm thick for longspan slabs forming part of a beam and carrying heavier loads The thickness of a slab will depend on the use and span of the slab

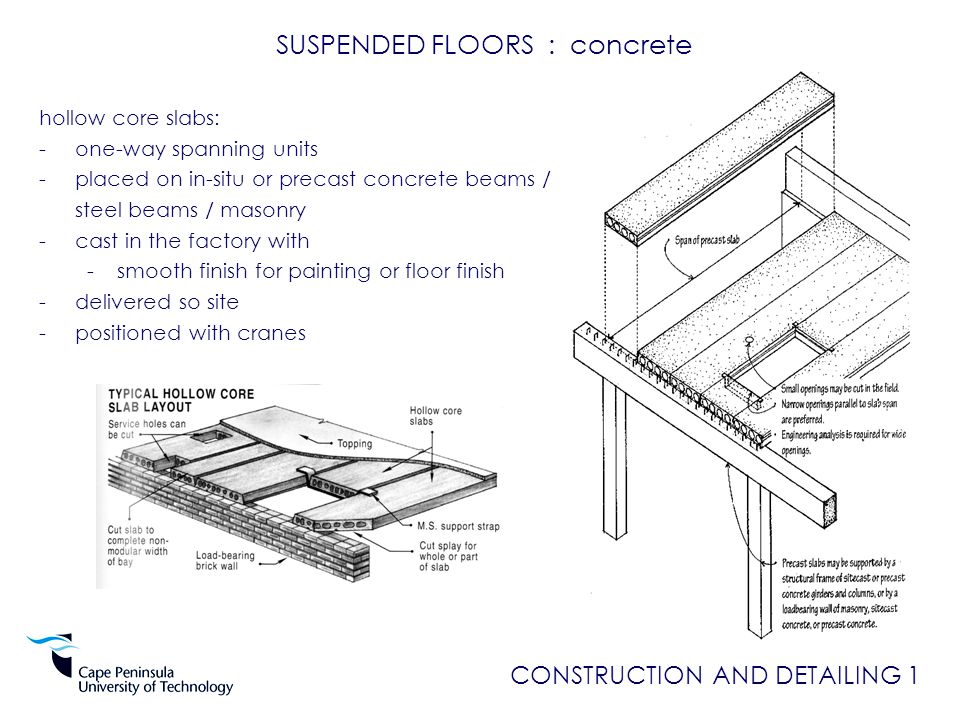

MG3 – External masonry cavity wall, suspended concrete slab £ 300 – £ 550 External masonry cavity wall, suspended concrete slab, insulation below slab Update Amended to full fill cavity wall, parge coat and service void CAD, SKP, JPEG & PDF FilesConcrete slabs between ground and first floor level greatly reduce sound transfer throughout the dwelling The mass of the slabs mean that they pro vide superior sound resistance to any traditional timber joist system In many cases sound transfer between levels is almost eliminated Fire Resistance A Safer Home The noncombustible nature of con crete makes it one of theSuspended slabs are made of concrete and steel mesh, the same as a ground slab They are normally prefabricated offsite, and transported by truck Some slabs have hollow channels running through them these 'hollow core slabs' are used to help reduce weight, and also to allow cabling and piping to be run through the slab

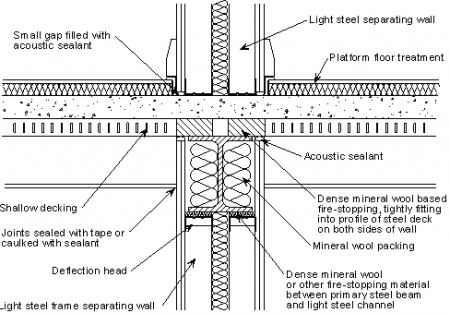

316 Timber Frame – Ground floor / separating wall junction – timber suspended floor 317 Timber Frame – Concrete ground floor / separating wall junction – insulation above slab 318 Timber Frame – Concrete ground floor / separating wall junction – insulation below slab 319 Timber Frame – Separating floor / separating wall 3At the turn of the 18th century, when construction techniques moved from boarded floors installed directly on the ground to suspended timber floors over a ventilated chamber, the innovation solved a significant problem Previously, floor timbers had been prone to damp and rot thanks to their direct contact with the moist ground Now, the free movement of air in the ventilated areaRIW/TD/154 Top of internal concrete retaining wall with ground bearing slab pdf RIW/TD/155 Insulated Concrete Framework & Masonry Below Ground Retaining Wall/Slab Interface pdf RIW/TD/156 Insulated Concrete Formwork & Masonry Below Ground Retaining Wall/Slab Interface Plus Gas Suspended Floor {product_related_downloadscount} Typical housing details pdf RIW/TD/1 Floor

Basic Easy How To Draw A Concrete Slab Section Detail In Autocad Tutorial Youtube

Problem 1 E The Floor System On The First Floor Chegg Com

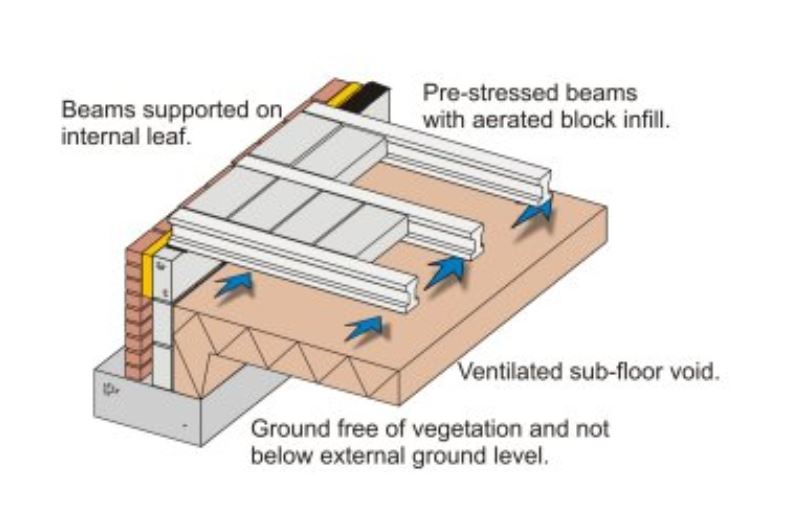

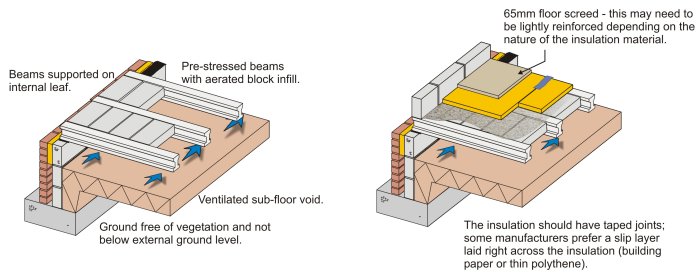

It is also possible to construct suspended concrete floors by using a precast product, for example the popular beam and block system Whichever construction method is used, it is usual to leave concrete surfaces quite rough to provide a key for the cementsand screed Upper floor concrete slabs Workers place concrete on a precast floor slab When it comes to upper floor concrete slabsHow thick is a suspended concrete slab? The construction of suspended concrete floors is similar to that of timber but can span greater distances, and offerings better sound insulation properties A simple reinforced concrete flat slab is not usually economical as a suspended floor spanning over 5 m Other solutions include precast concrete planks or precast concrete beams with concrete blocks

Concrete Slab Wikipedia

Concrete Vs Timber Floors

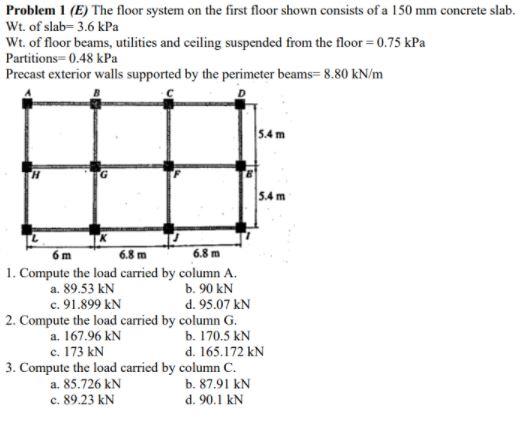

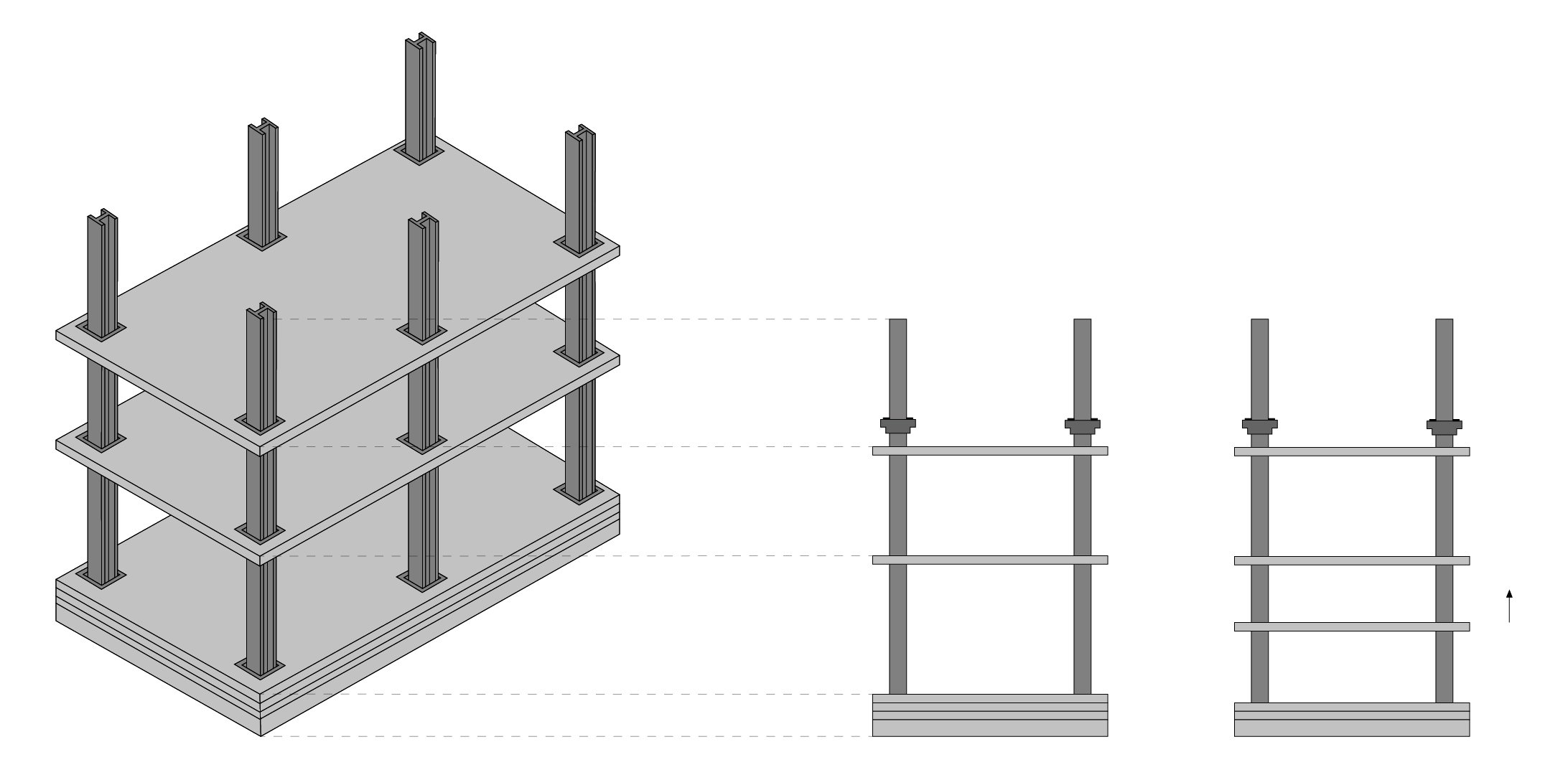

Selection of floor system Actual floor systems in buildings come in all sizes, shapes, and forms There are so many variables to any floor system such as different spans, offset spans, cantilevers, and the extent of continuity, the effects of beams, columns and walls on the slab system, etc that it is difficult to cover all situations in a limited series of chartsA suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading The floor spans between supports and will normally deflect under load to a dimension that is limited by the design used The prestressing of a concrete floor slab can eliminate its usual deflectionStrip Foundation Detail with ground bearing concrete slab Ground Bearing Concrete Raft Foundation Detail Strip Foundation Detail wit Suspended Concrete Slab Notes from the Building Regulations on Foundations General Requirements – Foundations The building shall be constructed so that the combined dead, imposed and wind loads are sustained and transmitted by it to the

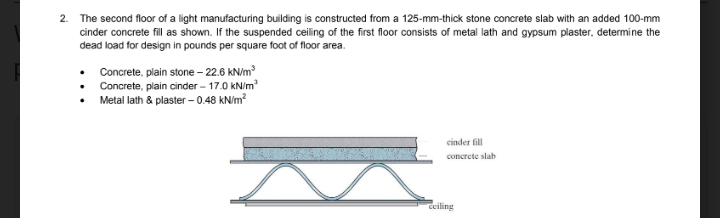

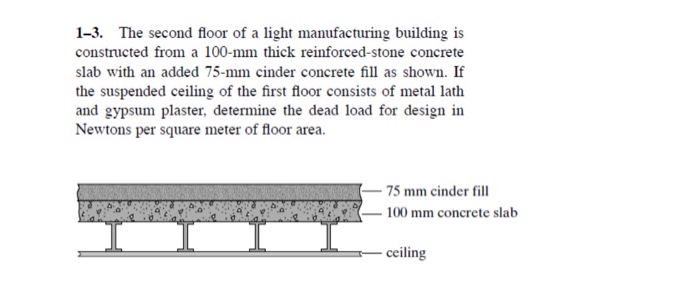

The Second Floor Of A Light Manufacturing Building Is Chegg Com

Greenspec Housing Retrofit Ground Floor Insulation

Suspended Concrete floors offer a lot more benefits and are normally made up of either concrete beams (more commonly known as Beam and Block) or concrete planks Both of these systems require a lot of handling and experienced professionals when being fittedGround floors Ground bearing solid concrete floors Guidance Diagram 9 Typical section through a ground bearing solid concrete floor and foundation Guidance Table 5 Examples of insulation for ground bearing floor slabs Suspended reinforced insitu concrete ground floor slabThe UK's leading manufacturer of prestressed Hollowcore Concrete Floors Milbank hollowcore floors (also known as slabs or planks) are prestressed concrete slabs with internal tubular voids, creating an efficient and lightweight plank that is far lighter than other floor slabs of equal thickness or strength The reduction in weight offers benefits such as lower transportation costs

Concrete Slab Wikipedia

Evolution Of Building Elements

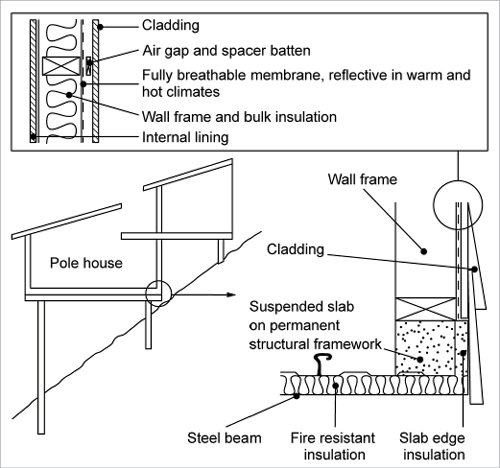

Detail Post Floor Details First In Architecture The ground floor is made up of suspended concrete slab or beam and block floor, supported by the external and internal load bearing walls, which transfer the loads to the foundations below Both precast concrete planks or slabs can be used, as well as cast in situ reinforced slabs along with beam and block systems Get Price SuspendedA selection of floor detail drawings including block and beam floors, timber suspended floors, solid ground floors and upgrade floor details Drawings are directly downloadable in Jpeg (1600 by 10px), DXF and DWG (cad) formats Note The Detail Drawings are applicable toMixing, transporting, and handling of concrete shall be properly coordinated with placing and finishing works In floor slab, begin concrete placing along the perimeter at one end of the work with each batch placed against previously dispatched concrete Fig 4 Concrete placement started from one end of the slab

Floor Slab An Overview Sciencedirect Topics

Prestressed Concrete First Floor First Floors Slab Construction Suspended Precast Concrete Floor

Typically there is a steel beam to reduce the span of the joists We commonly see LVL joists @ 16" oc with pressure treated plywood then vapor barrier then 34" of concrete topping slab with #3 bars for reinforcement @ 12" oc each way Both Boise Cascade and Weyerhauser have good technical bulletins on this construction practiceWhen first released in 1998, this publication covered slabonground floors in detail but contained only a limited outline of the alternatives available for suspended floors Comprehensive information on the latter was at that time provided in the Association's companion publication Guide to Suspended Concrete Floors for Houses(T40) published in 1991 Both earlier publications areSELECTING YOUR ROBUST DETAIL Houses will only need to be registered for Separating Walls The robustdetails® scheme does not apply to internal floors in houses When using Robust Details walls and floors in flats, details from the same construction group should be selected Refer to the relevant Combination Table to ensure compatibility

Lightweight Suspended Concrete

Concrete Floor Slab Construction Process The Constructor

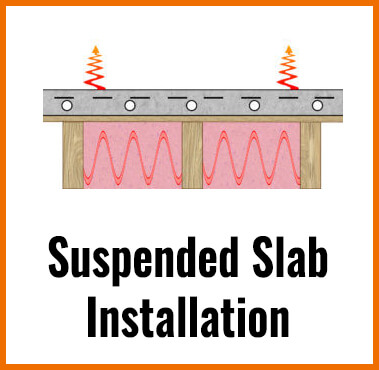

Ground bearing floors can include insulation either below or above the concrete slab, Suspended floors are usually insulated in such a way that they offer reduced thermal mass and respond quickly to the heating system In the case of suspended concrete, the insulation is installed above the deck, either under a screed or timber boarding Suspended timber floors areThis chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 ContaminantsThickness of the slab is decided based on span to depth ratio specified in IS Minimum reinforcement is 012% for HYSD bars and 015% for mild steel bars The diameter of bar generally used in slabs are 6 mm, 8 mm, 10 mm, 12mm and 16mm The maximum diameter of bar used in slab should not exceed 1/8 of the total thickness of slab

Suspended Floors All You Need To Know Thermohouse

Suspended Floors All You Need To Know Thermohouse

Thickness of concrete slab depends on loads and size of the slab In general, 6 inch (150mm) slab thickness is considered for residential and commercial buildings with reinforcement details as per design Thereof, How does a suspended slab work? The Suspended slabs consist of concrete and steel mesh They are usually prefabricated offsite and deliver through trucks Some plates have hollow passages through them these "hollow sheets" help to reduce weight and help in running wiring and pipes through them Suspended Slabs are typically buildup in two waysThree worked examples of precast unit floors in different building types are also included Structural design guidance provided in previously published three SCI publications, Design of composite beams using precast concrete slabs (P287), Design of asymmetric Slimflor beams with precast concrete slabs (P342)and Design of multistorey braced

Reinforced Concrete Design Class Project The Chegg Com

New Home Pouring A First Floor Suspended Slab Youtube

When renovating rooms with timber floors, it is often possible to replace the timber with a concrete slab for added thermal mass and quietness underfoot These slabs can be suspended on the original subfloor walls and footings, or if the old floor is close to the ground they can be an infill slab on fillOpenings in Concrete Floor Slabs BUILDINGS If you took an advanced concrete design course, you probably had a good introduction to the design of twoway slabsAlthough all multistory buildings require multiple small slab penetrations for routing of plumbing, fire protection piping, and ductwork between floors and larger openings for stairwells and elevator shafts, your courseSuspended floors are the norm for first floors (and above), but are also excellent for creating a level ground floor over uneven ground Alongside being cheap and easy to construct, timber floors benefit from being able to be adapted on site if need

How To Reinforce Concrete Slab On Ground To Control Cracking For Construction Pros

Concrete Slab Floor Construction Branz Renovate

Following a reputable concrete floor slab construction process will ensure that the slab lasts a sustained period Defects in construction can compromise the structure of the property and lead to expensive repairs (which may be covered by the builder's warranty) Ensure that you engage a reputable builder who has experience Here is a summary of the concrete slab constructionSuspended Timber Ground Floors consist of the finished timber floorboards being attached to floor joists, which are suspended above the subfloor of the foundation These floor joists are raised above the subfloor on small supporting walls called tassel walls (or sleeper walls) A wallplate is then attached to the top of the tassel walls, on which the floor joists rest on A damp proofHomespan is a revolutionary concrete flooring system consisting of flat precast concrete planks generally 600mm wide and 150mm deep Designed for residential use on both ground and first floor levels, it will carry domestic loading for spans up to 5m and is therefore cost effective

Sweet Home 3d Forum View Thread How Can The Floor Be Inside The Top Of The Lower Level

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

The ground must have a layer of concrete poured across, with a ventilated gap of at least 150mm to prevent moisture gathering and affecting the condition of any parts of the build, including timber joists if the floor you are installing is also timber371 Rafters on floor deck 372 Rafters on dwarf wall 38 Roof panels 381 Roof panel connections 39 Flat roof – Joist and decking 310 Dormer in Section 311 Dormer in Perspective view 312 Parapet detail – joists perpendicular 313 Parapet detail – joists parallel Details in Section 4 External Walls 41 Ground Floor 42 Intermediate floor – Joist parallel 43The original wall damp proof course (DPC) was designed to protect the timbers, skirting boards and plaster from rising damp The damp proof course is usually made from black bitumen, slate or plastic, and should be should be visible below the timber joists By laying a concrete slab you may alter the original level of the floor and bury the DPC

Q Tbn And9gcsoo00pmp Jo39lntwqiman Kyqnkiizr2egma 29un93tjzu39 Usqp Cau

Suspended Garage Slab From Design Build Specialists Steel Concepts

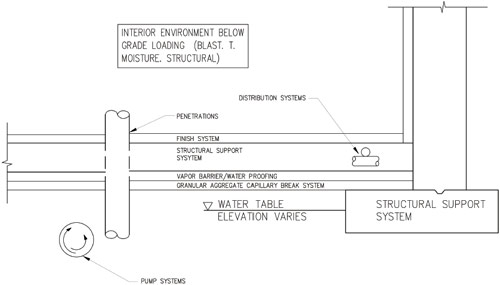

Suspended concrete slab is referred to a cement slab that is not in contact with the ground This type of and plywood as floor supports for the concrete The forming is very similar to that of framing floor of a house except concrete is a lot heavier than normal residential live load and dead load The 6 inch suspended slab in detail 21 weighs 75 pounds per square foot but the The concrete floor slab itself provides structural support for floor loads and suitable backup for floor coverings and finishes Base Floor Slab—Waterproof System A typical base floor slab where the design criteria include controlling moisture migration and water vapor transmission into the interior space can be referred to as a waterproofSOLID FLOOR INSULATION OVER SLAB To meet min U value required of 022 W/m²K Solid ground floor to consist of 150mm consolidated wellrammed hardcore Blinded with 50mm sand blinding Provide 100mm ST2 or Gen2 ground bearing slab concrete mix to conform to BS over a 10mm gauge polythene DPM, DPM to be lapped in with DPC in walls Floor to be insulated over a VCL on slab

Pin By Fire Protection Services Los A On Useful Info About Fire Protection Prevention Concrete Deck Suspended Ceiling Systems Fire Protection

Farm Structures Ch5 Elements Of Construction Floors Roofs

Concrete slabs that form the ground floor of a building may be either supported on beams (called a suspended slab) or supported directly on the subsoil, (via hardcore, for example) called a 'groundbearing slab' When a concrete slab forms part of the roof construction of a building, it is normally referred to as the 'roof slab' Types of

Insulation For Ground Floors Designing Buildings Wiki

Suspended Floors All You Need To Know Thermohouse

Assignment 1 Construction Design Abpl By Nesia Cahyono Issuu

Concrete Slabs

Answered 2 The Second Floor Of A Light Bartleby

First Floor Concrete Slabs What You Need To Know Eco Built

Mix Design Fundamentals Considerations For Concrete For Slabs On Ground Construction Specifier

6 Ground Floors Construction Studies

Suspended Slabs

Evolution Of Building Elements

Concrete Vs Timber Floors

Benefits Of A Suspended Floor The Shed House

E5mcff31 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Monolithic Slab Suspended Slab Cement Slab

1 3 The Second Floor Of A Light Manufacturing Chegg Com

Concrete Slab Types Construction Cost And Applications The Constructor

1

Lift Slab Construction Wikipedia

Installing Radiant Floor Heating Systems Behler Young

Frequently Asked Questions At First Floor Slabs

Structure Magazine Creating An Opening In Existing Floors

Detail Post Floor Details First In Architecture

Builder S Engineer Suspended Ground Floor Slabs

Frequently Asked Questions At First Floor Slabs

Construction Method Of Concrete Slab On Grade Concrete Slab Slab Concrete Floors

Typical Concrete Floor Construction Rwanda 24

How Is A Ground Floor Slab Constructed

Suspended Slab Subfloor Build

Figure B 10 Figure B 10 Alternative Floor Slab Detail The Suspended Reinforced Concrete Garage Workshop Plans Concrete Workshop Plans

Detail Post Floor Details First In Architecture

Concrete Slab Abis

How To Design An Ideal Floor For Warehouse And Logistics Facilities

Building Guidelines Concrete Floors Slabs

Building A First Floor Slab And Walls With Concrete Youtube

2

Building Guidelines Drawings Section B Concrete Construction

Floor Systems Steelconstruction Info

Building Guidelines Concrete Floors Slabs

Concrete Formwork For Slabs

1

Farm Structures Ch5 Elements Of Construction Floors Roofs

Evolution Of Building Elements

First Floor Slabs Concrete Slab Contractors Near Me

Polyethylene Under Concrete Slabs Greenbuildingadvisor

Concrete Slab Floors Yourhome

Ground Floor Insulation Below Concrete Slab Polyfoam Xps

First Floor Concrete Slabs What You Need To Know Eco Built

Q Tbn And9gcttjz3x5dph2qk Zk1wzuibsguzgtcn 4sdf1uyusei Yzqqnd9 Usqp Cau

E5mcpf32 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Detail Post Floor Details First In Architecture

How To Design An Ideal Floor For Warehouse And Logistics Facilities

Concrete Slab Floors Yourhome

How Are Suspended Slabs Built Build

Concrete Construction Smarter Homes

Structure Magazine Creating An Opening In Existing Floors

Fbe 03 Building Construction Science Lecture 3 Floor

Concrete Slab Wikipedia

Eurima Suspended Concrete Floors

Build Diy Suspended Concrete Ground Floors

Construction And Detailing 1 Ppt Video Online Download

What Size I Beam For Suspended Concrete Slab

Suspended Concrete Slab Suspended Slab Cement Slab

Building Construction I Sofia Sebastian 1 Ppt Download

Q A Solid Wood Floors Over Concrete Slabs Jlc Online

Concrete Floor Slab Construction Process The Constructor

Minimum Thickness Of Concrete Slab Beam Column Foundation The Constructor

Suspended Garage Slab From Design Build Specialists Steel Concepts

Suspended Ground Floor Slab Reinforcement Avi Youtube

Detail Post Floor Details First In Architecture

5 Things To Look For When Inspecting A Suspended Concrete Slab

Construction Of First Floor Slab Casting Work Pachalibhairav

Insulating Over A Structural Slab Jlc Online

Floor Structure Guide

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

Download Ground Bearing Floor Slab Full Size Png Image Pngkit

5 Things To Look For When Inspecting A Suspended Concrete Slab

Radiant Floor Heating Tubing Installation Methods Radiantec

Concrete Slab Floors Yourhome

Building Guidelines Drawings Section B Concrete Construction

Floor Slabs Wbdg Whole Building Design Guide

コメント

コメントを投稿